When expanding your manufacturing operations or starting a new industrial venture, the decision to buy used industrial equipment can be one of the smartest financial moves for your business. With new machinery costs soaring and delivery timelines extending beyond 6-12 months, the used equipment market offers immediate solutions at 40-60% cost savings. For Small and Medium Enterprises (SMEs) that contribute 30% of India’s GDP and employ over 110 million people, purchasing quality used machinery has become essential for competitive growth.

India’s used construction equipment market is growing at an impressive 15% annually, while industrial equipment platforms are revolutionizing how businesses discover and purchase machinery. Whether you’re browsing industrial classifieds on IndusFact.com or exploring traditional dealers, understanding the used equipment landscape can transform your capital efficiency and operational capabilities.

Table of Contents

Why Buy Used Industrial Equipment?

Immediate Cost Benefits

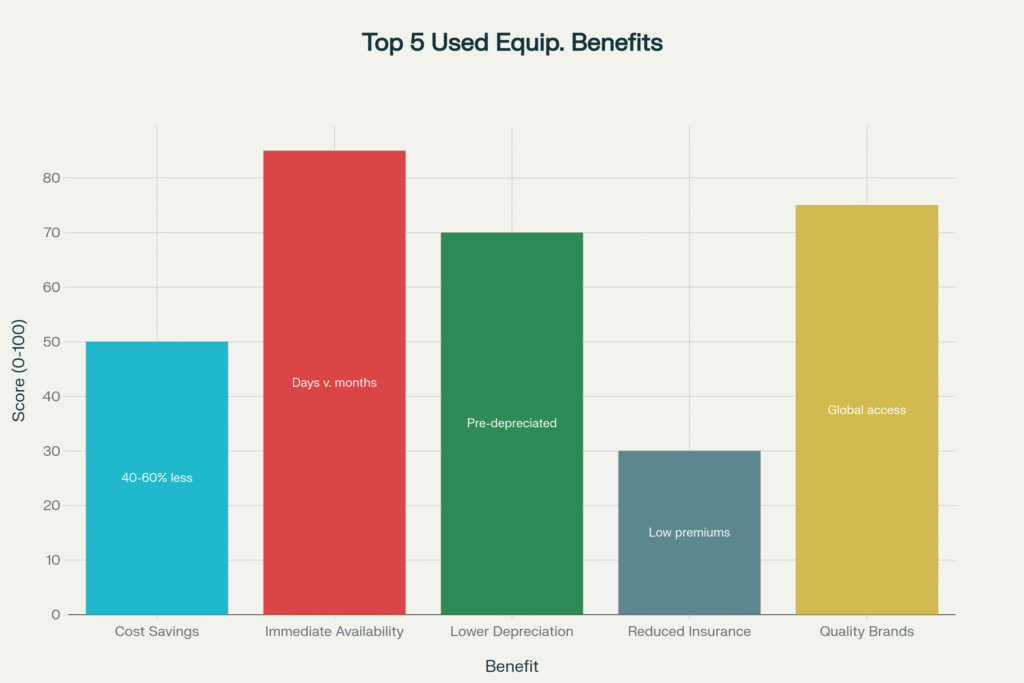

The most compelling reason to buy used industrial equipment lies in substantial cost savings. Used machinery typically costs 40-60% less than comparable new equipment, allowing businesses to reinvest savings into other critical areas like workforce training, marketing, or working capital. For construction equipment, buyers can save 30-60% on purchase prices, while avoiding the steep depreciation that new machinery experiences in its first year of operation.

Lower insurance premiums and reduced tax obligations provide additional financial advantages. Since insurance costs are based on replacement values rather than purchase prices, used equipment generates significantly lower annual insurance expenses. Additionally, buyers pay reduced GST on lower purchase amounts, further enhancing cost efficiency.

Operational Advantages

Immediate availability stands as a crucial competitive advantage in India’s fast-paced industrial environment. While new equipment often requires 6-12 month delivery windows due to global supply chain constraints, used machinery can typically be deployed within days or weeks of purchase decisions. This rapid deployment proves invaluable when replacing failed equipment or scaling operations to meet unexpected demand.

Access to proven technology and performance data provides buyers with insights unavailable for new equipment models. Used machinery comes with operational histories and documented performance metrics that inform purchasing decisions, reducing uncertainty about equipment capabilities and reliability.

Types of Equipment Perfect for Used Purchases

Construction and Earthmoving Equipment

Earthmoving equipment accounts for approximately 70% of India’s construction equipment market, making it highly active in secondary markets. Popular categories include excavators, backhoe loaders, bulldozers, wheel loaders, and motor graders. These machines typically offer 10-15 year operational lifespans, making 3-5 year old equipment particularly attractive for cost-conscious buyers.

Manufacturing Machinery

CNC machines, lathes, and machining centers remain excellent choices for used purchases due to their durability and slower technology obsolescence rates. Material handling equipment including forklifts, conveyors, and industrial trucks also perform well in used markets due to standardized designs and reliable operational characteristics.

Specialized Industrial Equipment

Food processing, packaging, and printing machinery maintain strong secondary market activity, often available from reputable manufacturers at competitive prices. Used equipment from countries like Germany, Japan, and Italy frequently incorporates advanced technology and robust build quality, enabling Indian manufacturers to compete globally at fraction of new equipment costs.

Essential Steps When You Buy Used Industrial Equipment

Research and Requirements Definition

Before you buy used industrial equipment, clearly define your operational requirements and budget parameters. Research specific machinery types, manufacturers, and model specifications that align with your production needs. Understanding market prices for similar equipment helps establish realistic budgets and provides negotiation leverage.

Consider not only purchase prices but additional costs including transportation, installation, commissioning, and potential repairs or upgrades. Setting comprehensive budgets prevents unexpected expenses and ensures informed decision-making.

Thorough Inspection and Evaluation

Professional inspection represents the most critical step when you buy used industrial equipment. Comprehensive evaluation should examine engine performance, hydraulic systems, electrical components, structural integrity, and operational accuracy. For precision equipment like CNC machines, tolerance testing ensures machinery meets manufacturing requirements.

Request complete maintenance records and operational history to understand equipment condition and remaining useful life. Service histories indicate responsible ownership and help predict future maintenance requirements and costs. Hour meter readings reveal usage intensity and help assess remaining equipment life.

Seller Verification and Documentation

Purchase from reputable sellers with established track records. Research seller reputation through customer reviews, testimonials, and market presence. Registered companies with transparent business practices provide better transaction security and recourse options.

Verify all legal documentation including ownership certificates, NOCs from financiers, and GST compliance. For imported equipment, ensure proper customs clearance and compliance certificates are available.

Where to Buy Used Industrial Equipment

Online Industrial Marketplaces

Industrial classified platforms like IndusFact.com provide comprehensive access to used equipment listings across diverse categories and geographical locations. These platforms enable detailed specification comparison, direct seller communication, and often include verification services to ensure listing accuracy.

Online marketplaces offer significant advantages including comparative pricing, detailed equipment information, and direct seller contact. Advanced search filters enable buyers to quickly identify equipment matching specific requirements including brand, model, year, location, and price range.

Traditional Channels

Industrial auctions remain popular venues for equipment acquisition, offering competitive pricing through bidding processes. Major industrial centers including Mumbai, Chennai, Bangalore, and Delhi host regular auction events featuring diverse machinery categories from plant closures and capacity reductions.

Established dealer networks and machinery hubs provide another reliable channel, often offering inspection services, basic refurbishment, and limited warranties.

Financing Your Used Equipment Purchase

Banking and NBFC Solutions

Leading banks including SBI, HDFC, and Axis Bank offer machinery loans specifically designed for used equipment. Loan amounts typically range from ₹25 lakh to ₹10 crore with 3-8 year tenure options, while NBFCs including Bajaj Finserv provide collateral-free financing up to ₹80 lakh.

Loan-to-value ratios for used equipment generally range from 60-80%, requiring modest down payments while maintaining competitive interest rates. Many lenders offer faster processing times and flexible documentation requirements for used equipment purchases.

Government Incentives

Credit Linked Capital Subsidy Scheme (CLCSS) provides interest subsidies up to 15% on machinery loans, while various state government industrial promotion schemes may provide additional benefits depending on equipment type and usage application.

Smart Negotiation and Risk Management

Market Intelligence

Comprehensive market research forms the foundation of successful negotiations. Compare prices across multiple platforms, understand seasonal pricing patterns, and research equipment depreciation rates to establish fair market values.

Budget establishment before negotiations helps maintain discipline and prevents emotional decision-making, while building relationships with sellers often yields better terms than aggressive bargaining approaches.

Risk Mitigation

Technology obsolescence represents primary concern, particularly for equipment older than 10-15 years. Verify that machinery meets current industry standards and safety requirements, while ensuring spare parts availability and technical support access.

Professional inspection and expert consultation minimize risk exposure and can reveal potential issues before purchase completion. Consider obtaining limited warranties or service agreements when available to provide additional protection.

Leveraging IndusFact.com for Your Equipment Needs

Industrial classified platforms provide centralized access to diverse equipment listings with detailed specifications, high-quality photographs, and direct seller contact information. Advanced search capabilities enable efficient equipment discovery, while verified seller programs help ensure listing accuracy and reduce fraudulent postings.

Price comparison features and market trend analysis help buyers make informed decisions and identify fair market values, while mobile-responsive platforms ensure equipment discovery can occur anywhere, enabling faster decision-making and reduced opportunity costs.

Making Smart Equipment Investment Decisions

The decision to buy used industrial equipment represents a sophisticated business strategy that balances cost efficiency with operational requirements. Success depends on comprehensive market research, thorough equipment evaluation, and strategic timing. By understanding market dynamics, employing proper inspection techniques, and maintaining realistic expectations about risks and benefits, businesses can successfully acquire quality industrial equipment at significant savings.

With India’s industrial sector projected for continued strong growth, the used equipment market offers sustainable competitive advantages for businesses willing to invest time and effort in successful transactions. Whether you’re expanding manufacturing capabilities, replacing aging equipment, or starting new operations, mastering used equipment procurement through platforms like IndusFact.com can significantly impact your bottom line and growth trajectory.

The key lies in viewing used equipment purchases not as compromises but as strategic investments that optimize capital deployment while maintaining operational excellence. When executed properly with due diligence and professional guidance, buying used industrial equipment becomes a powerful tool for business growth and competitive advantage in today’s challenging economic environment.

You must Register or Login to post a comment